Hybrid Vehicle Code P0A80

HVBMSs, like those found in hybrid vehicles whose malfunction triggers code P0a80, are designed to monitor charging levels and conditions within battery packs and provide input signals reflecting individual cell voltage, temperature, and resistance values directly back into HVBMS and PCM for analysis.

High Voltage Battery Pack

An electric vehicle’s high-voltage battery pack serves as its motors’ heart and source of power. Constructed from individual nickel metal hydride or lithium-ion cells wired together in series and parallel configuration, battery packs typically feature cells distinguished by internal resistance, nominal voltage, and capacity ratings.

A battery pack is constructed on an adjustable frame designed to evenly distribute its weight and provide a low center of gravity. This frame consists of top and bottom shells anchored together by spacers inserted between battery modules or blocks (see Fig 6.13), secured to them via countersunk head screws.

One major drawback of battery packs is their susceptibility to corrosion where metals come into contact. From copper posts that connect individual modules, such as copper posts for each battery pack module, to bus bars connecting all modules, any amount of corrosion can undermine its integrity and cause irreparable harm—including breaking physical connections between modules and reducing the charging capabilities of your battery pack.

Corrosion may cause short-circuiting between battery cells and the vehicle’s chassis, which is highly dangerous due to the high voltage. When this happens, an electrical arc could spread through the chassis into the battery, causing permanent damage and potentially costly replacement costs.

Battery packs present another significant danger: they transmit vibrations to battery cells, damaging their internal structure and leading to fatigue failure of terminal connectors and bus bars between modules. Furthermore, vibrations may induce resonances within pack assemblies, leading to delaminations between battery layers.

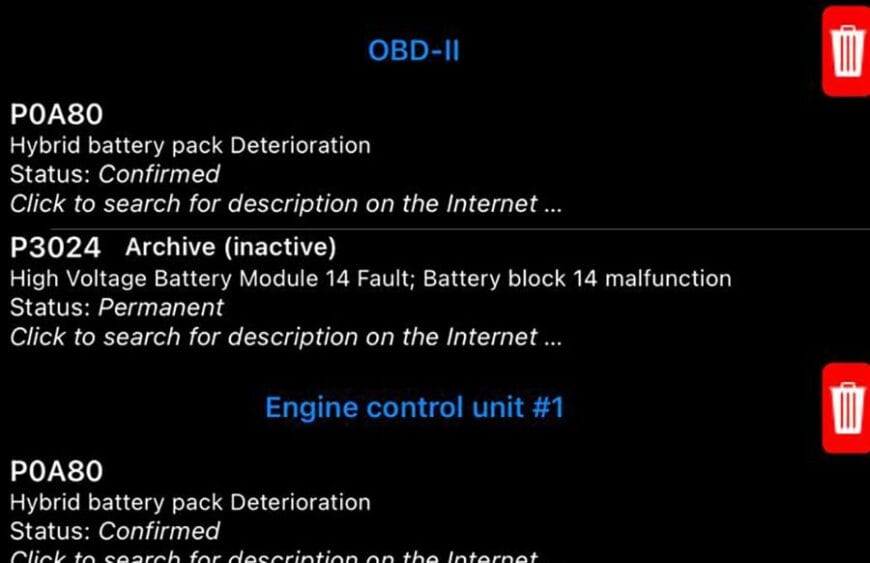

Modern CAN-based vehicle systems make these issues relatively straightforward to diagnose. The PCM (Powertrain Control Module) monitors each battery module by providing input signals that reflect resistance, voltage, temperature, and other parameters about each module’s resistance and voltage; when these values don’t correspond with expected values, the PCM logs code P0A80 to indicate weak or defective battery modules have been identified.

Busbar Connectors

Most hybrid vehicles use nickel-metal-hydride or lithium-ion battery packs consisting of individual modules (made up of multiple cells) connected via busbar connectors or cables and assembled into “blocks.” A battery management system (HVBMS) monitors their charging level by monitoring input signals such as cell resistance, voltage, and temperature. If any readings indicate deviation from expected values, HVBMS will alert the powertrain control module by setting code P0A80.

Corrosion within a battery pack or its connections often triggers this code on HVBMSs. Copper bus bars often become subject to corrosion due to environmental elements or chemicals used to charge and condition batteries. When these connections corrode, current flowing through them can reduce the voltage, which is detected by the HVBMS’s voltage sensor and reported back as “dropped voltage.”

This can lead to the battery ECU setting a weak block code, creating havoc for the mechanic and the vehicle owner. A mechanic may be able to clear out bus bar connections and give life back to some batteries, but if too many of the cells are damaged or nearing the end of their lifespan, all will likely require replacement.

At each inspection, a mechanic will use a multimeter to test each battery cell for voltage and resistance and test HVBMS sensors according to manufacturer specifications and procedures to ensure they operate optimally. If an HVBMS sensor doesn’t meet specifications or procedures, it should be replaced immediately.

HVBMS sensors will be tested by applying a known load or source to the battery pack and measuring each module’s voltage. Readings should come close to zero volts; otherwise, they indicate something may be amiss within HVBMS and needs replacing immediately.

High Cell/Circuit Resistance

This code is activated when the Battery Management System identifies an imbalance between individual battery cell voltage levels. An increase in internal resistance between cells can create significant differences in voltage that lead to premature cell failure and self-discharge faster than expected, rapidly decreasing usable capacity and ultimately leading to rapid degradation in overall battery performance.

The BMS monitors the voltages and temperatures of each cell within the battery pack using sensors and then compares those data points to determine if there is any significant variance. When an alarm is triggered, a “P0A80” code sounds, illuminating a warning to alert drivers.

One of the primary causes of this code is a loose or damaged connection between batteries and their respective bus bar connectors. This is often caused by corrosion forming on these busbars, which reduces current flow through each connection. BMS modules are designed to send less charge through each busbar connector to compensate.

Another cause for this code may be high resistance within the battery itself. To compensate, BMS modules can increase their charge output when their voltage falls below an acceptable threshold level, helping restore cell voltage up to acceptable levels and allowing BMS to resume sending charges through cell busbar connectors.

If the vehicle displays this code, it is strongly suggested that its owner take their hybrid car to a professional mechanic with access to necessary tools such as automotive code readers, powertrain diagnostic scanners, and battery monitoring systems to identify this problem accurately. If its battery is at fault, a replacement will likely need to be installed to eliminate the code and allow regular operation to resume.

Temperature Discrepancy

P0A80 is an urgent code, as it indicates issues with one of the primary components in your hybrid-powered vehicle: its battery. For this reason, we strongly advise consulting a professional mechanic immediately to diagnose and resolve this problem, or else risk further degradation of your battery pack.

The HV Battery Management System (HVBMS) uses the code P0a80 to detect a temperature discrepancy among modules within your hybrid car’s high-voltage battery pack. Multiple ammeter/temperature sensors are strategically placed throughout your battery pack to provide data to PCM via controller area network regarding cell and module temperature and resistance values for comparison, then used by HVBMS to regulate battery state-of-charge and condition when an input signal that indicates inconsistent temperatures or voltages is received by HVBMS it will trigger failure signal and illuminate malfunction indicator lamps to alert PCM of potential battery pack issues or malfunction.

These sensors monitor module pairs. If any deviation of more than 0.2V occurs between two of the 28 module pairs, your Prius will set an error code. Furthermore, its HV ECU must always be capable of reading the SOC of each of these modules—even while under load.

Replacing your hybrid battery pack may be your best option, although this can be very expensive. An alternative would be having it refurbished by professionals to extend its proper function and efficiency for many more years than just a few. In either case, promptly addressing this issue is vital to avoid further degradation or buying an entirely new hybrid car battery.